Introduction

Skeleton buckets are essential tools for excavation, ideal for separating materials like dirt, gravel, and rocks. Their design, with wide gaps or tines, allows for easy material sorting. However, using a skeleton bucket can come with challenges. In this article, we'll cover three common problems you could face when using a skeleton bucket and provide practical solutions to optimize its performance and lifespan.

Material Too Small or Getting Stuck

Problem with Small Material

One of the primary challenges when using a skeleton bucket is handling smaller materials. The open design of the bucket allows for larger debris to stay inside, while finer particles like dirt, sand, and small rocks pass through the gaps between the tines. This can be beneficial for separating materials, but when you're trying to sort smaller rocks from dirt, this can become problematic. If the material you’re trying to sift is smaller than the spacing between the tines, it will fall straight through, leading to inefficiency.

To address this, you might need to consider a different attachment, such as a hydraulic screening bucket. These buckets have smaller gaps between the bars, allowing for finer material separation. While they are a more expensive option, they can be a great solution for projects where the material is finer and requires more precision in sorting.

Material Stuck Between Tines

Another common issue is when material gets stuck between the tines of the skeleton bucket. Although this doesn’t usually affect the overall function of the attachment, it can be annoying. Depending on the type of material, debris like sticks or larger pieces can get wedged between the tines, making it more difficult to continue sorting or sifting efficiently.

The solution for this problem is relatively simple: use a hammer, rod, or other similar tools to dislodge the material stuck between the tines. This can quickly clear the blockage and allow you to resume your work. It’s a minor inconvenience, but one that can be avoided with regular checks and clearing of debris during operation.

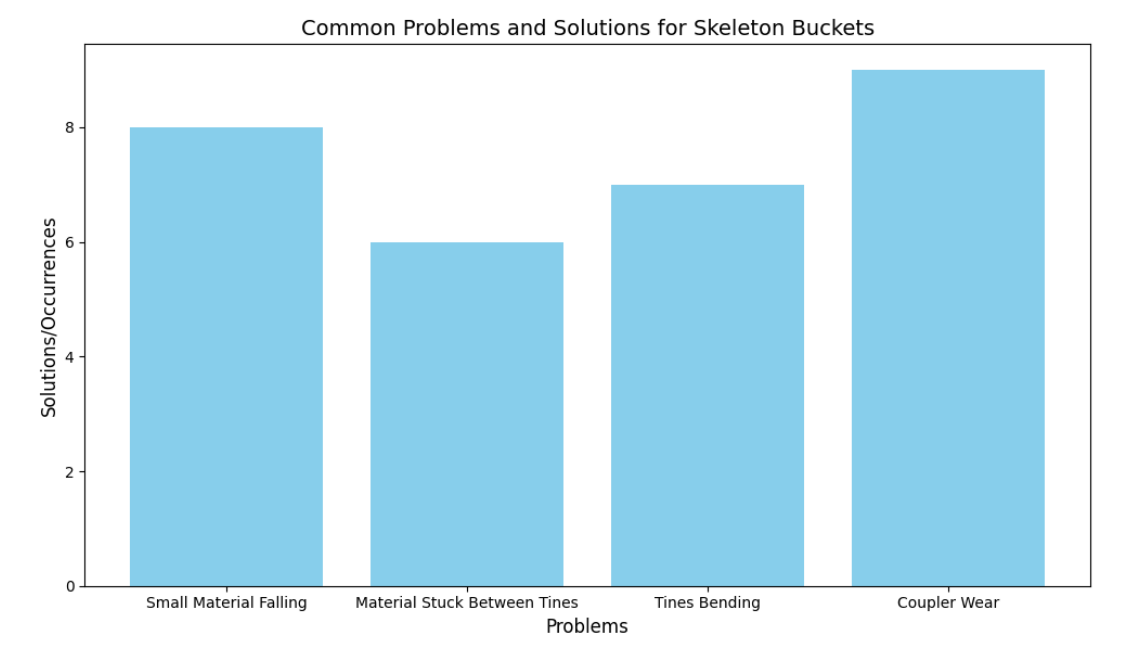

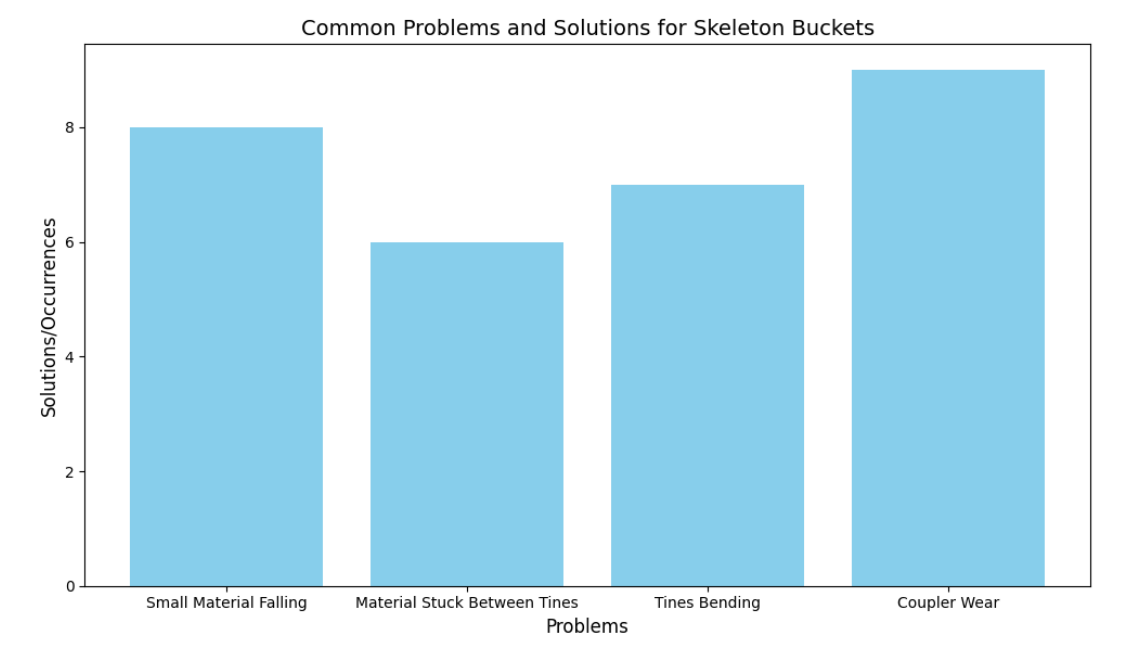

Problem | Description | Solution |

Small Material Falling Through | Small material falls through gaps in the tines | Use a hydraulic screening bucket for finer material separation |

Material Stuck Between Tines | Larger debris gets stuck between the tines, obstructing efficient work | Use a hammer or rod to clear stuck material |

Tines Bending | Tines bend due to the open design and pressure from tough materials | Break up materials first, choose a reinforced skeleton bucket |

Coupler Wear | Repetitive shaking motion wears out the coupler | Mount the bucket directly to the excavator for better stability |

Tines Bending

The Design Issue

While skeleton buckets are excellent tools for material separation, their open design makes them more susceptible to damage than solid buckets. The tines of a skeleton bucket are typically made from thick steel to withstand harsh materials, but they can still bend or twist under pressure. This happens because the gaps between the tines reduce the overall structural integrity of the attachment. Imagine trying to break a stick by spreading it out—if you try to break several sticks at once, they will snap more easily than if they are held tightly together. The same principle applies to skeleton bucket tines.

In scenarios where heavy or compacted material is being processed, the tines are under more strain, and without proper reinforcement, they can bend or twist. This is especially true when the bucket is used in harsh conditions or overused without sufficient breaks.

How to Prevent Bending

To prevent your skeleton bucket tines from bending or twisting, it’s essential to take a few precautionary steps. First, consider breaking up the material you're working with before using the skeleton bucket. For example, use a ripper tooth or a digging bucket to loosen tough materials before attempting to sift them with the skeleton bucket. By doing so, you reduce the amount of force that is directly applied to the tines, preventing unnecessary stress.

Additionally, when purchasing a skeleton bucket, look for one with added support. Some models feature reinforced tines with additional steel straps welded in place to offer extra support. This reinforcement can go a long way in preventing bending and extending the life of the bucket. Always check for signs of wear or stress on the tines, and replace or repair them before they fail completely.

Feature | Benefit |

Reinforced Tines | Prevent bending by adding extra support |

Steel Straps Welded in Opposite Direction | Reinforce the tines, enhancing durability |

Thick Steel Construction | Improves strength, resists bending and wear |

Wearing Out Your Coupler

Understanding the Risk

Another significant issue when using a skeleton bucket is the potential for wearing out the coupler. The coupler connects the attachment to the excavator, and when using a skeleton bucket, the shaking motion required to separate materials can put a lot of strain on this component. This type of operation requires the bucket to shake vigorously to loosen smaller materials, and over time, this repetitive motion can cause the coupler to wear out.

While replacing pins and links is part of regular maintenance, excessive shaking can cause damage to the coupler itself, resulting in costly repairs. If you’re using a coupler for quick bucket changes, this wear can add up quickly and lead to unexpected downtime.

Recommended Solution

The best way to avoid excessive wear on your coupler is to mount the skeleton bucket directly to the excavator instead of using a coupler. Direct mounting, using bucket pins, will provide more stability and reduce the strain on the coupler. This simple change can help avoid long-term damage to the coupler and the associated repair costs. While direct mounting may take more time for attachment changes, it can significantly improve the durability of your excavator and attachments.

Skeleton Bucket Type | Features | Best For |

Fixed-Tine Skeleton Bucket | Rigid design, cost-effective, minimal moving parts | General material sorting |

Hydraulic Grapple Skeleton Bucket | Hydraulic tines for gripping and lifting debris | Demolition, brush clearing, scrap handling |

Adjustable-Spacing Skeleton Bucket | Customizable tine spacing for different debris sizes | Mixed waste sorting |

Conclusion

Skeleton buckets are essential for excavation, offering efficient material separation. However, common issues like material falling through tines, bending tines, and wear on the coupler can arise. These challenges can be addressed by breaking up tough materials, choosing reinforced buckets, and directly mounting the bucket. Regular maintenance ensures optimal performance, helping you avoid costly repairs and extend the life of your equipment. For long-lasting, high-performance buckets, YF Bucket provides reliable solutions tailored to your needs.

FAQ

Q: What is a skeleton bucket used for?

A: A skeleton bucket is an excavator bucket attachment used for sorting and separating materials like dirt, gravel, and rocks.

Q: Why does small material fall through the tines of a skeleton bucket?

A: The gaps between the tines allow smaller materials to fall through, making it difficult to separate smaller debris. A hydraulic screening bucket may be a better option for finer material.

Q: How can I prevent the tines of my skeleton bucket from bending?

A: To avoid bending, break up tough material first and choose a bucket with reinforced tines or additional support.

Q: What causes wear on the coupler when using a skeleton bucket?

A: The shaking motion of the bucket during material separation puts stress on the coupler, leading to wear. Mounting the bucket directly to the excavator helps avoid this issue.

Q: Can a skeleton bucket be used with all excavators?

A: Yes, skeleton buckets are compatible with most excavators. However, ensure the bucket is the right size for your specific machine.

Q: How often should I maintain my skeleton bucket?

A: Regular inspections and maintenance are key. Check for wear, clean the bucket after use, and lubricate moving parts to ensure long-lasting performance.