Introduction

Mini excavators are powerful, compact machines that can tackle a wide variety of tasks, from digging to demolition. But with the right excavator attachments, their versatility multiplies, making them even more valuable on the job site.

In this guide, we’ll explore the top five excavator attachments that enhance mini excavators’ capabilities, helping you maximize efficiency and complete projects faster.

Key Attachments for Mini Excavators

Mini Excavator Bucket

Why It’s Essential

The mini excavator bucket is arguably the most commonly used attachment and is an essential tool for almost any excavation task. Whether you are digging trenches, moving soil, or clearing debris, the bucket is a staple for every mini excavator. Its versatility allows it to perform numerous functions, including digging for foundation footings, trenching for utilities, and general material handling. A variety of bucket types, such as standard, grading, and trenching buckets, can further enhance your mini excavator’s capability.

Key Features

Mini excavator buckets come in different designs tailored to specific tasks. For instance, the standard bucket is ideal for general digging and loading, while a grading bucket is more suitable for leveling or smoothing soil. Trenching buckets, with their narrower design and sharper teeth, are perfect for digging precise, deep trenches. These buckets are designed for durability, often made from high-strength steel that resists wear, ensuring they perform well even in the toughest of conditions.

● Durability: Constructed from high-strength steel, making it resistant to wear and tear.

● Versatility: Available in various sizes and shapes to accommodate different tasks.

● Efficiency: Reduces the time and labor needed for digging, moving material, and other excavation-related tasks.

Bucket Type | Purpose | Best For | Features |

Standard Bucket | General excavation and material handling | Digging loose soil, rubble, sand | Durable, versatile, suitable for a wide range of tasks |

Grading Bucket | Smoothing and leveling surfaces | Grading land, finishing work | Smooth bottom for level results |

Trenching Bucket | Digging narrow, deep trenches | Utility work, drainage systems | Sharp, robust teeth for compacted soil |

Hydraulic Breaker

Purpose and Benefits

Hydraulic breakers are indispensable for demolition projects. These attachments utilize high-impact force to break through hard surfaces like concrete, asphalt, or even rock. For jobs that involve breaking down structures or removing large, solid obstacles, a hydraulic breaker can significantly improve efficiency and productivity. This attachment eliminates the need for manual labor or additional machinery like jackhammers.

Efficiency Advantages

A hydraulic breaker can perform the same job as multiple workers using manual tools but at a fraction of the time and physical effort. It's ideal for tough demolition tasks, such as breaking concrete foundations or rock extraction for roadworks. In addition, hydraulic breakers are designed to be energy-efficient, providing maximum impact force while minimizing fuel consumption.

● Time-Saving: Breaks down tough materials quickly, saving hours of manual labor.

● Cost-Effective: Reduces the need for additional machinery and manual labor.

● Improved Safety: Reduces physical strain on workers and minimizes safety risks associated with manual tools.

Auger Attachments

Applications for Precision Drilling

Auger attachments are designed for drilling tasks, such as creating holes for posts, trees, or foundations. They offer precision drilling and are particularly useful for tasks requiring uniform hole sizes. Mini excavator augers come in various sizes and bit configurations to handle different soil conditions, making them ideal for utility installations, tree planting, and fence post setups.

Key Features

Mini excavator augers are designed with adjustable depths and bit sizes, allowing for customization based on the project requirements. Whether you're working with soft soil or more compacted material, auger attachments offer versatility and efficiency in drilling tasks. The auger bit itself typically features a helical design that helps remove soil as it drills, ensuring that holes are clean and consistent.

● Adjustable Depth: Customize the drilling depth for specific project needs.

● Versatile Bit Sizes: Choose from various sizes to meet your project specifications.

● Durable Design: Reinforced steel bits allow for long-lasting use even in tough conditions.

Grapple Attachments

Why It’s a Game Changer

Grapple attachments add significant value to a mini excavator by allowing it to handle large, irregularly shaped materials such as logs, rocks, and debris. This attachment is ideal for land clearing, demolition, or any task requiring the manipulation of oversized or cumbersome materials. It allows for greater precision and control, making it easier to move materials safely and efficiently.

Uses and Benefits

The grapple is often used in projects like land clearing, debris removal, and material handling. Its design typically includes a set of powerful jaws or claws that can open and close around materials, providing a secure grip. The ability to rotate and tilt makes it ideal for handling difficult-to-grab objects, like logs or construction waste.

● Enhanced Material Handling: Easily handle irregular or bulky materials with precision.

● Increased Versatility: Great for clearing land, sorting debris, and performing tasks that require lifting and moving large objects.

● Efficient: Reduces manual labor and speeds up material handling tasks.

Tiltrotator

Increased Flexibility for Mini Excavators

A tiltrotator is one of the most advanced attachments for mini excavators, offering unparalleled flexibility. It allows the bucket or tool to rotate 360 degrees and tilt at angles up to 45 degrees. This increased range of motion helps operators perform complex maneuvers, especially in confined spaces where repositioning the excavator is difficult.

Productivity Gains

Tiltrotators eliminate the need for frequent machine repositioning, which can save time and reduce operator fatigue. They are especially valuable for intricate tasks like grading, slope excavation, and working in tight spaces. By reducing the amount of time spent repositioning the mini excavator, tiltrotators can significantly improve project efficiency.

● Increased Efficiency: Save time by reducing the need for machine repositioning.

● Versatility: Excellent for tasks requiring precise control, such as trenching or landscaping.

● Operator Comfort: Reduces operator strain by minimizing the need to adjust the machine frequently.

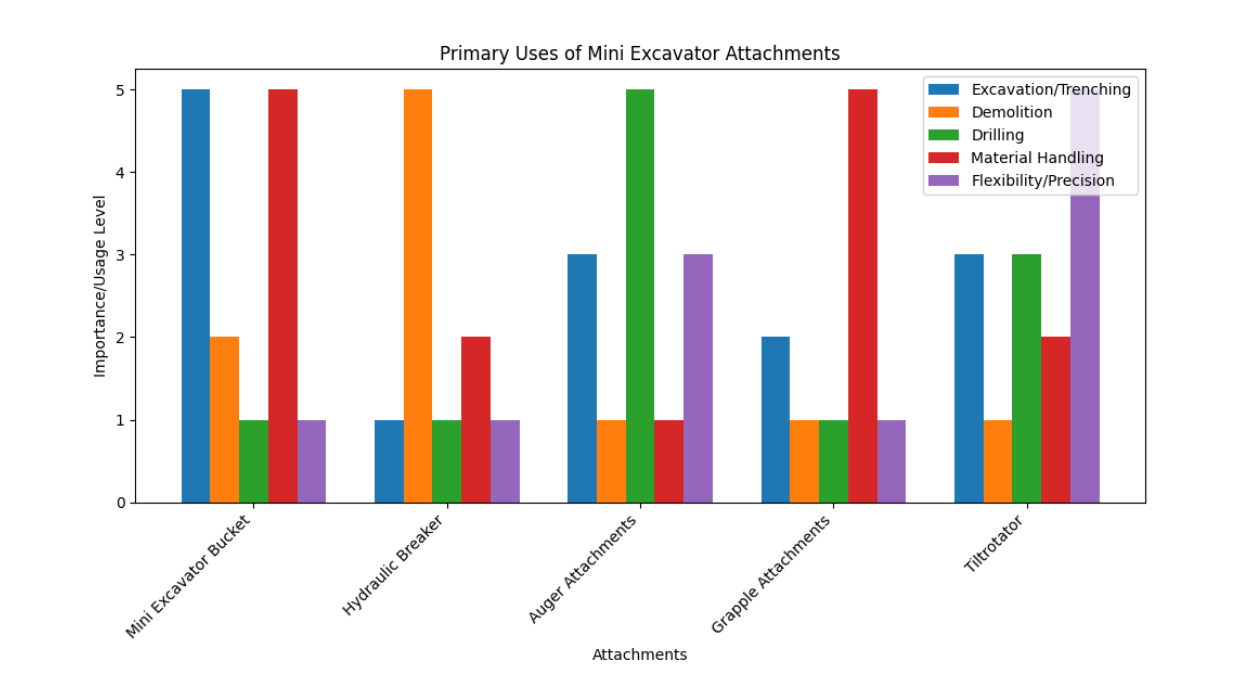

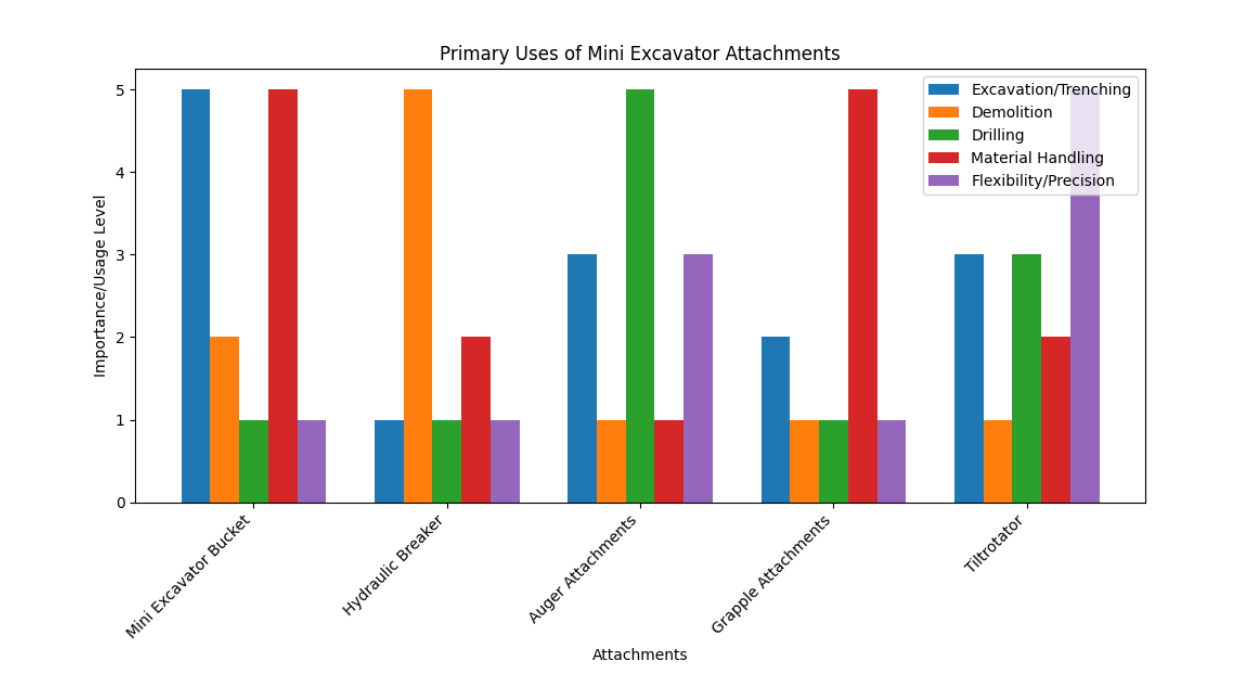

Attachment | Primary Use | Key Benefits | Best For |

Mini Excavator Bucket | Digging, trenching, material handling | Versatile, durable, enhances digging efficiency | Excavation, trenching, landscaping |

Hydraulic Breaker | Demolition (concrete, rock, asphalt) | Powerful impact, reduces manual labor | Demolition, site prep |

Auger Attachments | Precision drilling | Drills holes efficiently for posts and foundations | Landscaping, post installation |

Grapple Attachments | Handling irregular materials (logs, debris) | Improves material control, great for land clearing | Material handling, land clearing |

Tiltrotator | Increased flexibility for attachments | Allows rotation and tilting for precise tasks | Excavation, trenching, landscaping |

How to Choose the Right Attachment for Your Mini Excavator

Assessing Your Project Needs

To ensure that you’re maximizing the potential of your mini excavator, it’s crucial to assess the specific requirements of your project. Whether you're digging trenches, breaking concrete, or planting trees, there’s a specialized attachment for each task. By identifying the nature of your work, you can select attachments that enhance your mini excavator’s capabilities, improving both efficiency and output.

● Excavation: Buckets and augers are great for digging and material removal.

● Demolition: Hydraulic breakers and grapples are perfect for breaking hard materials.

● Landscaping: Augers, grading buckets, and tiltrotators help with precise control in tight spaces.

Machine Compatibility

Before purchasing or renting an attachment, check the specifications of your mini excavator to ensure that the attachment is compatible. Each mini excavator has its own set of hydraulic flows, pressure capacities, and mounting requirements. Ensuring compatibility will prevent issues with performance and ensure that the attachment operates optimally.

● Hydraulic Flow: Make sure the attachment matches your mini excavator’s hydraulic requirements.

● Mounting: Check that the attachment’s coupler system aligns with your mini excavator’s design.

Maintenance Tips for Mini Excavator Attachments

Regular Maintenance

Maintaining your mini excavator attachments is essential to ensure their longevity and optimal performance. Regular cleaning and lubrication can prevent wear and tear, helping your attachments function at their best for longer. Be sure to follow the manufacturer’s guidelines for maintenance schedules and lubrication intervals.

● Cleaning: Regularly clean attachments to remove dirt and debris.

● Lubrication: Apply grease to moving parts to reduce friction and prevent rust.

Inspection and Storage

Routine inspections are necessary to detect any wear or damage before it affects performance. Always check for loose bolts, worn-out parts, or any other issues. When not in use, store your attachments in a dry, covered area to prevent rust and other damage caused by exposure to the elements.

● Storage: Keep attachments stored in a safe, dry place to avoid corrosion.

● Inspection: Conduct thorough checks to ensure attachments are working correctly.

Attachment | Maintenance Tip | Importance |

Mini Excavator Bucket | Regular cleaning and lubrication | Prevents wear, maintains bucket efficiency |

Hydraulic Breaker | Check for cracks and clean regularly | Extends the tool’s lifespan and ensures peak performance |

Auger Attachments | Inspect drill bits for wear and tear | Keeps precision and efficiency in drilling tasks |

Grapple Attachments | Grease moving parts and inspect for damage | Prevents rust and ensures smooth operation |

Tiltrotator | Clean and inspect hydraulic systems | Ensures optimal rotation and tilt functionality |

Conclusion

This article highlights the top five mini excavator attachments: buckets, hydraulic breakers, augers, grapples, and tiltrotators. These attachments enhance the versatility of mini excavators, ensuring efficient performance for various tasks. By choosing the right attachments, operators can boost productivity, reduce costs, and improve overall efficiency. For high-quality attachments, YF Bucket offers reliable options to maximize your mini excavator's potential.

FAQ

Q: What are the best attachments for a mini excavator?

A: The top five attachments for a mini excavator are buckets, hydraulic breakers, augers, grapples, and tiltrotators. Each enhances the excavator's versatility for various tasks.

Q: Why is a mini excavator bucket important?

A: The mini excavator bucket is essential for tasks like digging, trenching, and material handling. It's versatile and helps improve efficiency in different work environments.

Q: How does a hydraulic breaker improve mini excavator performance?

A: A hydraulic breaker is ideal for demolition work. It allows the mini excavator to break concrete, rock, or asphalt with ease, reducing manual labor.

Q: What is the purpose of auger attachments for mini excavators?

A: Auger attachments are used for precision drilling, such as installing fence posts or digging for foundations. They improve productivity in tasks that require accuracy.

Q: How do grapple attachments enhance a mini excavator's capabilities?

A: Grapple attachments are perfect for handling large or irregular materials like logs, rocks, and debris. They are essential for land clearing and material handling.

Q: What is the advantage of using a tiltrotator with a mini excavator?

A: A tiltrotator provides increased flexibility by allowing the mini excavator’s bucket to rotate and tilt, improving efficiency in excavation and trenching tasks.