Introduction

Excavator buckets are essential in construction, mining, and landscaping. They face tough conditions, constantly exposed to abrasive materials and impacts. Over time, this leads to significant wear and costly repairs. In this guide, we’ll explore practical strategies to protect your excavator bucket, extending its lifespan and ensuring efficient performance.

Buy Excavator Buckets with Wear Protection

When investing in a new excavator bucket, one of the first things to consider is the durability of the material. Excavator buckets that come with added wear protection are designed to withstand harsh conditions and last longer.

Choosing Durable Buckets from the Start

Investing in an excavator bucket made from high-quality, wear-resistant materials is key to protecting your equipment. Many manufacturers offer buckets that are reinforced with additional steel layers, hardened edges, and specialized wear plates. These enhancements provide extra protection against the forces encountered while digging. Choosing a bucket that is pre-equipped with these protective features ensures that your equipment is better suited for the job and will last longer, reducing maintenance and repair costs over time.

Advantages of High-Quality Bucket Materials

The materials used to manufacture an excavator bucket play a critical role in its longevity and resistance to wear. Buckets made from high-strength steel or alloy materials are less likely to wear down quickly when exposed to abrasive surfaces like rocks, gravel, or compacted soil. These materials resist the high-impact forces encountered during excavation, providing better protection and increasing the bucket's durability.

Importance of Compatibility with Worksite Conditions

Choosing the right bucket for the specific conditions at your worksite is also vital. For example, a bucket designed for rocky terrain may require additional reinforcement on the edges and teeth to prevent damage. Understanding the materials you'll be working with and how they affect the wear on your bucket can help you select the right type of bucket for the job.

Use Bolt-on Wear Protection for Excavator Buckets

Adding bolt-on wear protection is an effective way to prevent damage to the edges of your excavator bucket. These protective components can be easily replaced when they wear out, saving you the cost of replacing the entire bucket.

What is a Bolt-on Blade?

A bolt-on blade is a replaceable, hardened steel attachment fixed to the edge of the excavator bucket. The blade acts as a sacrificial layer, absorbing the wear that would otherwise affect the bucket itself. Over time, as the blade gets worn down, it can be removed and replaced without needing to replace the entire bucket, making it a cost-effective solution for protecting your equipment.

Benefits of Using Bolt-on Wear Parts

The main advantage of using bolt-on parts is the ease of replacement. When wear occurs, only the worn part needs to be replaced, not the whole bucket. This can save both time and money in the long run. Moreover, these components provide targeted protection, ensuring that the parts most susceptible to wear are shielded. Bolt-on blades, wear strips, and edge protectors also reduce maintenance time, as they can be installed or swapped out quickly.

When and How to Replace Bolt-on Components

It’s important to monitor the condition of your bolt-on wear parts regularly. If you notice that the blade is starting to show signs of excessive wear or damage, it’s time to replace it. Replacing these parts is simple—just unbolt the worn component and install a new one. Regular checks will help you stay ahead of wear and ensure that your bucket remains in optimal condition.

Use the Right Excavator Bucket for the Job

Not all excavator buckets are created equal. Using the right bucket for the specific task at hand is essential for preventing unnecessary damage.

Selecting the Correct Bucket for Specific Tasks

For different types of work, a specialized bucket may be necessary. For example, using a general-purpose bucket to break up compacted soil can cause damage to the bucket’s teeth and edges. To prevent this, use a ripper attachment for breaking up hard materials before using the bucket. This helps protect the bucket from unnecessary wear. Similarly, avoid using a grading bucket to move heavy materials like concrete slabs, as this can lead to damage to the blade and teeth.

Importance of Choosing the Right Bucket Size

Choosing the right bucket size for your excavator is crucial. A bucket that is too large can cause excessive stress on the excavator, while one that is too small can lead to overloading. Both scenarios can lead to accelerated wear and potential damage. Ensure that the bucket you choose matches the excavator’s capacity, enabling it to operate efficiently without overstraining the machine.

Using Attachments Like Ripper Teeth to Protect the Bucket

Ripper teeth are specialized attachments designed to break through hard surfaces, such as compacted soil or rock. By using these teeth before digging with your excavator bucket, you reduce the strain on the bucket’s teeth and edges. This helps protect your bucket from unnecessary damage and ensures more efficient operation.

Regularly Inspect and Maintain Your Excavator Bucket

Routine inspection and maintenance are key to extending the life of your excavator bucket. By catching issues early and performing regular upkeep, you can prevent more serious damage from occurring.

Daily Inspections to Catch Early Damage

Conduct daily inspections to check for signs of wear and tear. Look for cracks, dents, and thinning areas on the cutting edges, teeth, and sidewalls of the bucket. If you catch damage early, it’s easier and more affordable to address. Regularly check that all pins, bushings, and bolts are secure, as loose components can exacerbate wear.

Cleaning Your Excavator Bucket

Cleaning the bucket after each use is an important part of maintenance. Mud, debris, and moisture can cause corrosion over time, especially when left to accumulate. Wash the bucket thoroughly after each use to prevent these elements from causing rust or other damage. Be sure to dry the bucket completely before storing it to avoid the development of rust.

Lubricating Moving Parts to Prevent Excessive Wear

Lubrication helps prevent friction and wear on the moving parts of the excavator bucket. Regularly grease the pivot points, joints, and other moving components to ensure smooth operation. This reduces the risk of mechanical failure and extends the overall lifespan of the bucket. It’s important to use the manufacturer-recommended grease to ensure compatibility and effectiveness.

Proper Excavator Bucket Storage and Handling

How you store and handle your excavator bucket plays a critical role in preventing damage. By taking the necessary steps, you can extend the bucket’s life and avoid costly repairs.

Protecting Your Bucket from Environmental Damage

When not in use, it’s important to store the bucket in a dry, sheltered area. Exposure to rain, snow, and extreme temperatures can cause rust, corrosion, and weakening of the metal over time. If you must store the bucket outdoors, using protective covers can provide an additional layer of defense against environmental elements. Covering the bucket helps keep moisture and dirt out, preventing damage from harsh weather conditions and extending the bucket’s durability.

Storage Practice | Benefit | Recommendation |

Store in a dry, sheltered area | Prevents rust and corrosion | Choose a storage area that is covered and protected from weather. |

Use protective covers | Shields bucket from environmental elements | If stored outdoors, always cover the bucket with weather-resistant covers. |

Keep away from extreme temperatures | Avoids metal weakening and corrosion | Ensure storage areas are temperature-controlled if possible. |

Handling the Bucket with Care

Improper handling can lead to unnecessary strain and deformation, which may compromise the bucket’s effectiveness. Always use the appropriate lifting equipment to move or store the bucket. This ensures the bucket is lifted safely and evenly, reducing the risk of bending or damaging the structure. Avoid dropping the bucket or striking it against hard surfaces, as these actions can cause immediate cracks or dents. Handling the bucket with care prevents potential long-term damage and ensures that it remains in optimal working condition.

Train Excavator Operators for Safe and Efficient Use

The way your operators handle the excavator bucket plays a significant role in its longevity. Proper training and techniques can prevent unnecessary damage, ensuring the bucket operates at its full potential and lasts longer.

Importance of Proper Operator Training

It’s essential to ensure that operators are well-trained in using both the excavator and the bucket. Skilled operators understand the limits of the machine and the bucket, which helps avoid situations that could cause wear or damage. Proper training also reduces the risk of mishandling, overloading, and unnecessary strain, all of which can shorten the bucket's lifespan and lead to costly repairs. Operators should be trained in safe operating techniques, machine limits, and maintenance basics.

Best Practices for Excavator Bucket Operation

To maximize the excavator bucket's lifespan, operators should avoid aggressive digging movements, excessive digging angles, and overloading the bucket. These actions place undue stress on the bucket, which accelerates wear and reduces efficiency. Encouraging operators to follow best practices—such as using the bucket within its design limits, avoiding unnecessary impacts, and practicing smooth, controlled movements—helps preserve the bucket and keep it performing optimally for longer.

Avoiding Overuse and Misuse

The excavator bucket should only be used for its intended purpose. Using the bucket as a pry bar, hammer, or for tasks it wasn’t designed for can lead to significant damage, shortening its operational life. Operators should be trained to recognize the limits of the bucket and use appropriate attachments for specific tasks, ensuring the right tool is used for each job. Misuse and overuse not only increase wear but can also lead to permanent damage to the bucket and the machine.

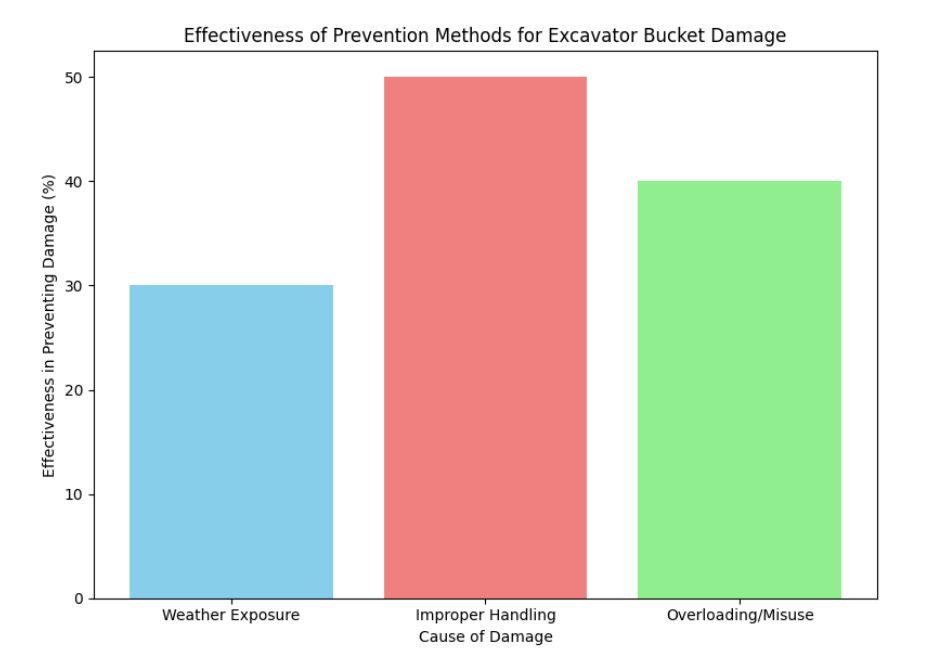

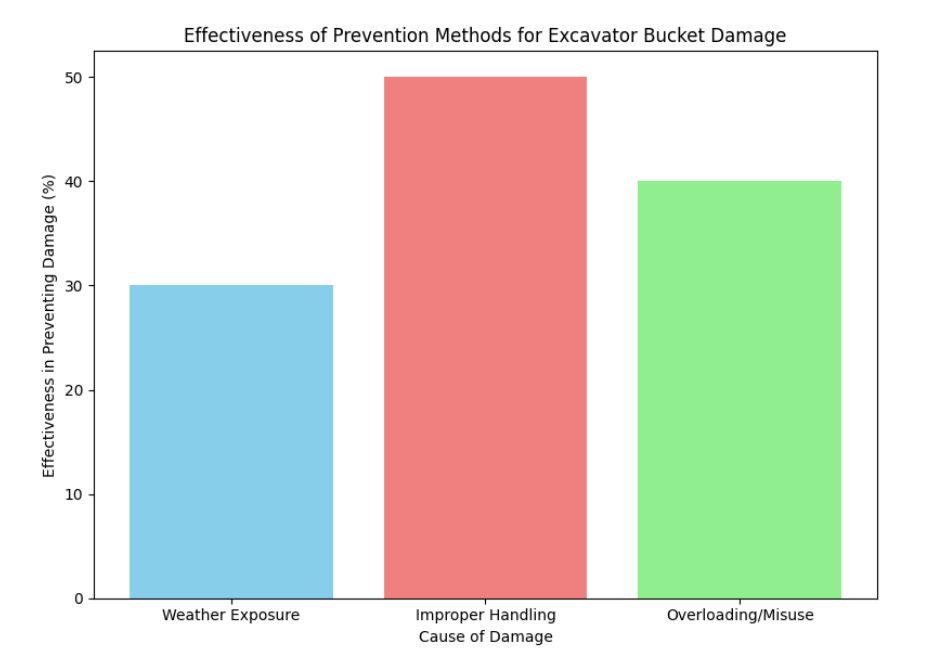

Cause of Damage | Prevention Method |

Exposure to weather (rain, snow, temperature) | Store the bucket in a dry, sheltered area or use protective covers. |

Improper handling (lifting, dropping, striking) | Use appropriate lifting equipment and avoid impacts with hard surfaces. |

Overloading or misuse | Train operators to use the bucket within its design limits and for its intended purpose. |

Implement Routine Maintenance to Maximize Bucket Life

Routine servicing and maintenance are essential to keep your excavator bucket in top condition. Regularly addressing small issues prevents them from becoming major problems.

Professional Servicing for Long-Term Protection

Scheduling regular maintenance with a qualified technician ensures that potential issues are identified early. Technicians can check for misalignments, internal wear, and other issues that might not be visible during routine inspections. Regular professional servicing helps to prolong the life of your bucket and ensures it operates efficiently.

Identifying and Replacing Worn Components Early

Monitor and replace components such as teeth, cutting edges, and wear plates as soon as they show signs of wear. Proactive replacement prevents further damage and ensures that the bucket continues to perform optimally.

Keeping Records of Maintenance and Inspections

Maintain a log of all inspections, repairs, and maintenance activities. This helps you track the condition of the bucket and ensures timely replacements. Keeping detailed records can also assist in identifying recurring issues, so you can take steps to address the underlying cause.

Conclusion

Protecting your excavator bucket is crucial for maintaining its efficiency and longevity. Investing in durable buckets, using bolt-on protection, and choosing the right bucket for the job can extend its life. Regular inspections and proper handling minimize damage risks. With proper operator training, you can reduce downtime and costly repairs. For high-quality excavator buckets that offer long-lasting performance, YF Bucket provides exceptional products designed for durability and reliability in tough working conditions.

FAQ

Q: How can I prevent my excavator bucket from getting damaged?

A: To prevent damage to your excavator bucket, invest in durable buckets with wear protection, use bolt-on wear parts, and select the right bucket for each job. Regular inspections and maintenance are also essential to catch damage early.

Q: What are the benefits of using bolt-on wear protection for an excavator bucket?

A: Bolt-on wear protection for your excavator bucket allows easy replacement of worn parts, saving time and money while extending the life of the bucket.

Q: Why is proper operator training important for protecting an excavator bucket?

A: Proper operator training ensures that excavator buckets are used efficiently, minimizing unnecessary stress and wear, ultimately protecting the bucket from damage.

Q: How do I choose the right excavator bucket for my project?

A: Selecting the right excavator bucket depends on the job type. Choose a bucket designed for specific tasks like grading or digging in compact soil to avoid premature wear.

Q: How often should I inspect my excavator bucket for damage?

A: You should inspect your excavator bucket daily for any signs of wear, cracks, or damage to the teeth and edges. Regular inspections help prevent costly repairs.

Q: Can using the wrong excavator bucket size cause damage?

A: Yes, using an incorrectly sized excavator bucket can overload the machine or cause excessive wear, leading to potential damage. Always match the bucket size to the machine's capacity.