You want to choose the right excavator bucket for your machine and job. This decision impacts both safety and efficiency. When you use a bucket that matches your excavator weight and the material you plan to move, you improve productivity and reduce costs.

Proper sizing means fewer passes and less fuel used.

A bucket that is too big or too small can slow projects, increase wear, and create safety risks.

The correct fit boosts lifting capacity and reduces manual labor.

| Bucket Size | Tool Weight | Cost |

| 8-inch | 37.3 lbs | $149.99 |

| 12-inch | 44.3 lbs | $200+ |

The YF Bucket Excavator Bucket stands out as a durable and versatile choice for 20-30 ton excavators. Its strong steel build helps you tackle tough jobs with confidence. Use this guide to match your excavator and bucket to your task for the best results.

Key Takeaways

Picking the right excavator bucket size helps keep things safe. It also makes work faster and saves fuel. It can make the project take less time.

Always choose a bucket size that matches your excavator’s weight. Think about the material you need to move. This helps stop damage and keeps people safe.

Look at the bucket size chart to find the best match. This helps your excavator work well and last longer.

Pick the right bucket type for your job. Some jobs need special buckets to work best.

Check your bucket often and take care of it. This helps it last longer and keeps work safe. Clean and oil the bucket after you use it.

Excavator Bucket Size Chart

To pick the best excavator bucket size, you first need to know the different excavator groups. You should match your machine with the right bucket for safe work. The excavator bucket size chart shows which bucket fits your excavator and job.

Excavator Size Categories

Excavators are sorted into groups by weight. Companies use weight to organize them. The chart below helps you find your machine’s group.

| Size Category | Weight Range (metric tons) | Weight Range (pounds) |

| Mini or Compact | 0 – 6 | < 13,227 |

| Midi | 6 – 10 | 13,227 – 22,046 |

| Standard/Full-Size | 10 – 90 | 22,046 – 198,416 |

Mini excavators are good for landscaping and small spaces. Midi machines do jobs like trenching and small demolition. Standard excavators handle bigger projects, such as roadwork and building foundations.

Bucket Size Recommendations by Weight

You should choose a bucket size that matches your machine’s weight and the material you want to move. The chart below lists common bucket sizes and uses for each group.

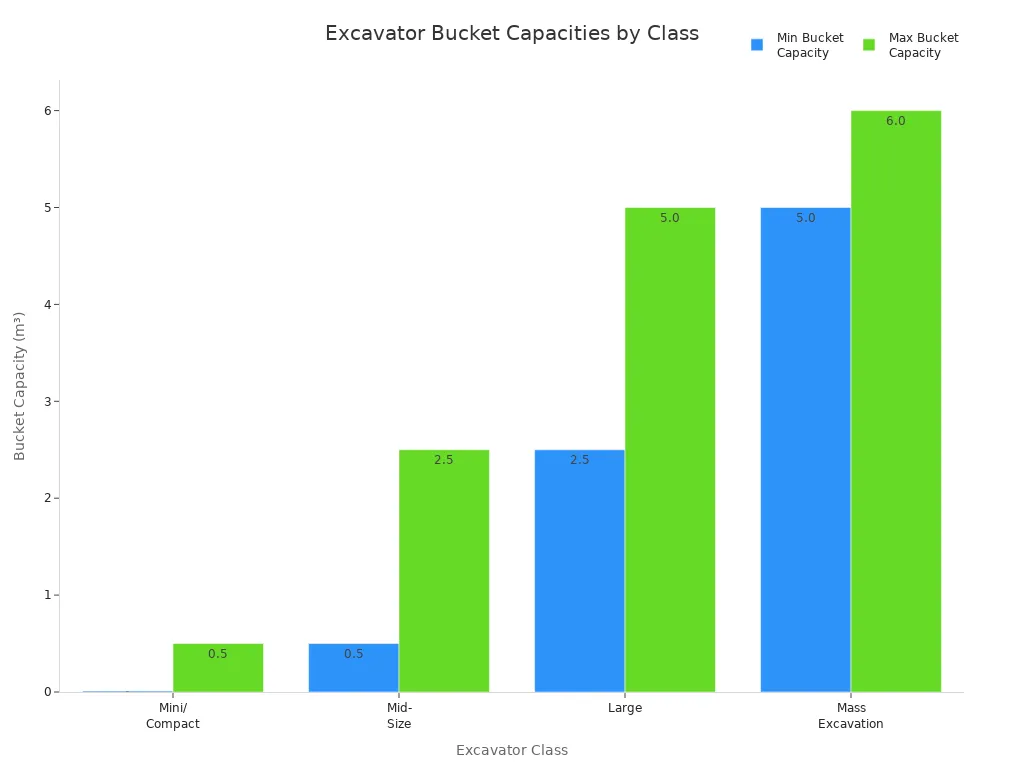

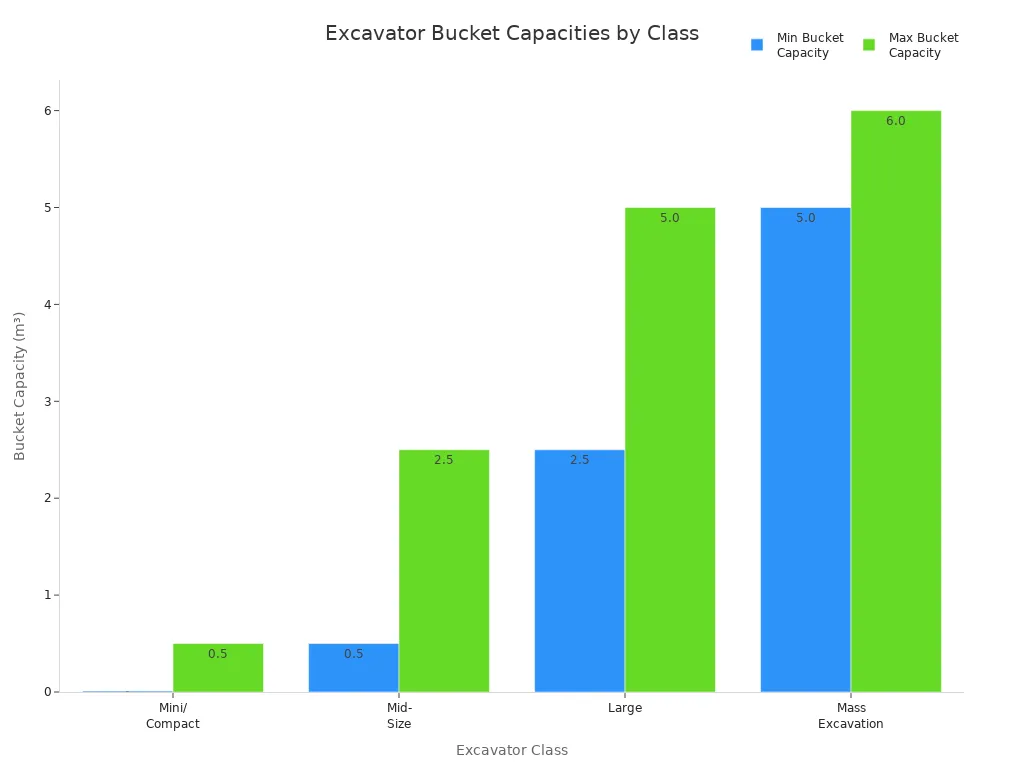

| Excavator Class | Operating Weight (Tons) | Typical Bucket Capacity (Cubic Meters) | Primary Applications |

| Mini/Compact | 1 – 10 | 0.01 – 0.5 | Landscaping, utility trenching, small demolition |

| Mid-Size | 10 – 40 | 0.5 – 2.5 | General construction, road work, building foundations |

| Large | 40 – 90 | 2.5 – 5.0 | Large-scale earthmoving, commercial excavation, quarrying |

| Mass Excavation | > 90 | 5.0+ | Open-pit mining, large-scale dredging, major infrastructure |

If you have a 20-ton excavator, pick a bucket width based on the material. For loose sand and topsoil, use a general-purpose bucket between 36 and 60 inches wide. Clay works best with a medium bucket from 24 to 36 inches. Demolition debris needs a heavy-duty bucket from 24 to 48 inches. Rocks need a strong bucket from 16 to 36 inches for better control.

Tip: Always look at your excavator’s manual for the right bucket size. This keeps your machine safe and stops overloading.

Example Excavator Size Chart Table

The chart below lets you compare bucket sizes, capacities, and uses. It helps you pick the best bucket size for your job.

| Excavator Weight Class | Recommended Bucket Width (inches) | Typical Bucket Capacity (cubic meters) | Best Applications |

| Mini (0–6 tons) | 6 – 24 | 0.01 – 0.3 | Landscaping, trenching |

| Midi (6–10 tons) | 12 – 36 | 0.3 – 0.6 | Utility work, small demolition |

| Medium (10–40 tons) | 24 – 60 | 0.6 – 2.5 | Roadwork, foundations, sewer |

| Large (40–90 tons) | 36 – 72 | 2.5 – 5.0 | Quarrying, commercial excavation |

| Mass Excavation (>90) | 60+ | 5.0+ | Mining, dredging |

The YF Bucket Excavator Bucket fits medium and large excavators from 20 to 30 tons. It holds 2.0 to 3.0 cubic meters and weighs 1,200 to 1,800 kg. You can use it for construction, mining, and tough digging jobs. Its strong steel build makes it a good choice for hard work. The YF Bucket fits many excavator models and meets safety and quality rules.

Note: Picking the right excavator bucket size helps your machine work better and last longer. Always use the bucket size chart to help you choose.

Bucket Capacity & Lift Ratio

Understanding Bucket Capacity

Before you dig, know how much your bucket holds. Bucket capacity means how much material fits inside at once. Companies measure this in cubic yards or cubic meters. You can look at the specs or figure it out yourself.

To find out, fill the bucket and pile material above the edge. This is called heaped capacity. The fill factor tells how well the bucket holds stuff. Using the right size bucket helps you finish faster and keeps your excavator safe.

Note: Bucket capacity changes how much you move each time. Bigger buckets carry more, but you need the right size for your machine.

Calculating Capacity & Lift Ratio

You want your excavator to stay safe. The lift ratio helps with this. The bucket load should be less than 75% of the max lifting weight. Bigger excavators lift more than small ones. A small excavator might lift one ton. A big one can lift ten tons or more.

Here are the steps to figure out bucket capacity and lift ratio:

Trace your bucket’s shape on paper or cardboard.

Draw the heap area above the edge.

Make a grid over the load area.

Count all the full squares in the grid.

Add up parts of squares to make whole ones.

Multiply the area by the bucket’s length for volume.

Use this number to check if your load is safe. Always match the bucket size to your excavator’s lifting power. This keeps your work safe and helps you get more done.

Excavator Bucket Types

Picking the right excavator bucket type helps you do your job well. Every bucket is made for a certain job and material. The table below shows the main types, what they do, and why they are useful.

| Bucket Type | Description | Applications | Advantages |

| General Purpose | Digs and loads soil, sand, gravel | Construction, landscaping, roadworks | Versatile, durable, many sizes |

| Heavy Duty | Handles rocks, concrete, and tough materials | Mining, quarrying, demolition | Withstands heavy wear, tough conditions |

| Rock | Reinforced for breaking hard rock surfaces | Quarrying, mining, foundation excavation | Reduces wear, handles sharp materials |

| Trenching | Narrow shape for digging trenches | Pipelines, drainage, utilities | Accurate, minimal soil displacement |

| Grading/Tilting | Tilts for grading and finishing work | Landscaping, slope grading, roadwork | Precision, easy contouring |

| Skeleton | Openings for sorting debris from soil | Demolition cleanup, waste segregation | Efficient material handling |

| V-Bucket | Digs V-shaped trenches | Irrigation, cable laying | Clean trenching, less soil moved |

| Mud | Wide, flat bottom for wet materials | Moving mud, soft ground | Prevents clogging, easy scooping |

| Frost | Reinforced teeth for frozen ground | Winter excavation, cold climates | Works in harsh conditions |

| Clamshell | Hinged for precise material handling | Dredging, bulk loading, vertical digging | Superior control, loose materials |

General Purpose Buckets

General purpose buckets are used for most digging jobs. They work with soil, sand, and gravel. These buckets fit many construction and landscaping tasks. You can pick different sizes for your excavator and material. General purpose buckets are strong and hold a lot for daily work.

Heavy Duty & Rock Buckets

Heavy duty and rock buckets are made with extra-strong steel. They have tough edges for hard jobs. You use them for mining, quarrying, and demolition. These buckets handle rocks and concrete. The YF Bucket Excavator Bucket is a good example. It uses strong steel and a smart design. It works with 20-30 ton excavators for big jobs. People say it helps them work faster and lasts longer, even in rough places.

Trenching & Grading Buckets

Trenching buckets are narrow. You use them to dig trenches for pipes or cables. They take out less dirt, so you fill trenches quickly. Grading buckets help you smooth and finish surfaces. You can tilt them for slopes, landscaping, and road grading. These buckets give you control and help you work neatly.

Specialty Buckets

Specialty buckets include skeleton, V-bucket, mud, frost, and clamshell. Each bucket solves a special problem. Skeleton buckets sort debris from dirt. V-buckets dig V-shaped trenches for irrigation or cables. Mud buckets move wet material without getting stuck. Frost buckets break frozen ground. Clamshell buckets grab loose or bulk material with care. You choose a specialty bucket when your job needs something special.

Tip: Always pick the right bucket size and type for your machine and material. This keeps your work safe and helps you finish faster.

Choosing Mini Excavator Bucket

Mini Excavator Size Chart

When you pick a mini excavator bucket, look at the size chart. The chart helps you find the right bucket for your machine. Mini excavator buckets come in sizes from 6 inches to 36 inches. Each bucket size works best for certain jobs and materials.

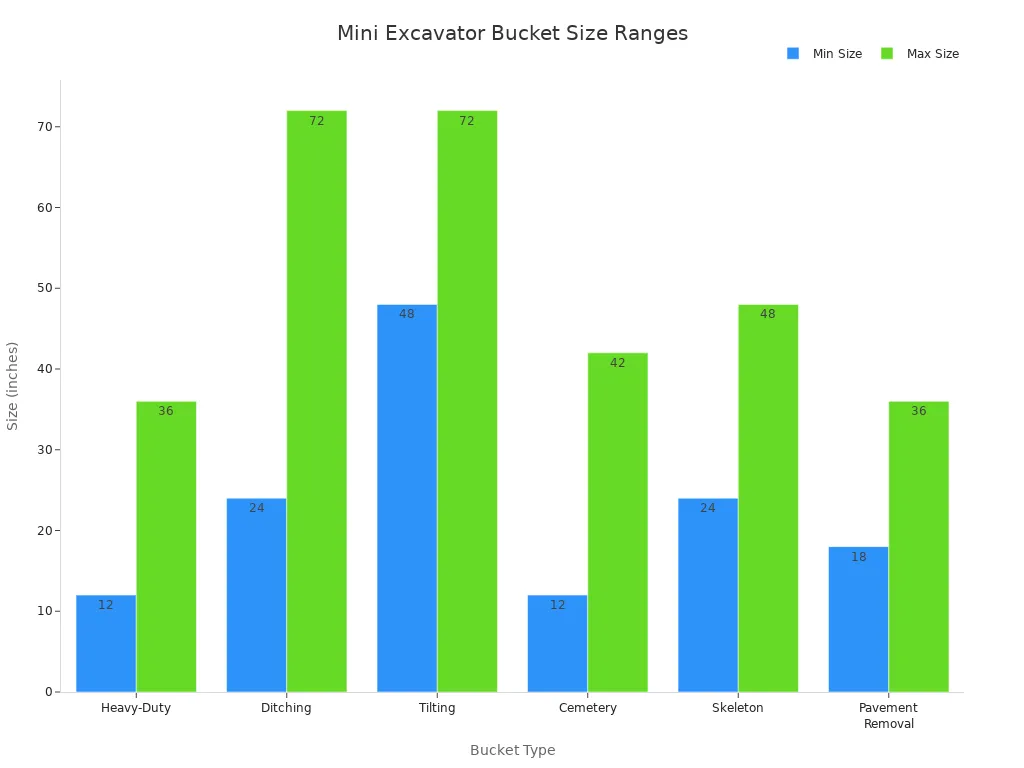

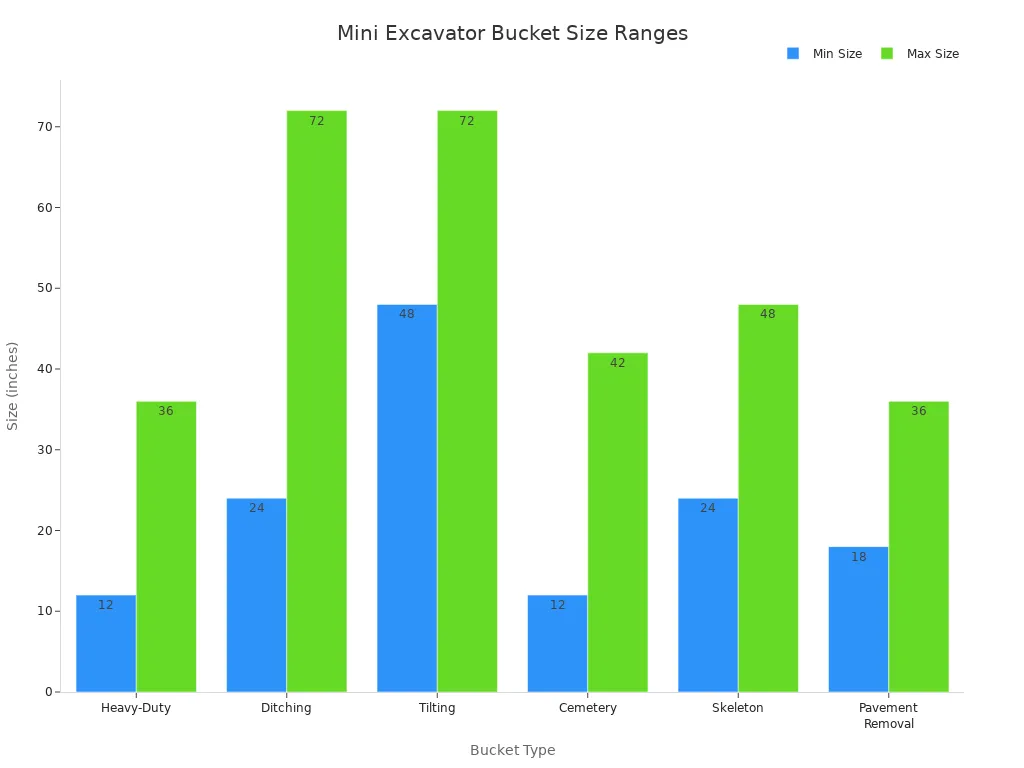

| Bucket Type | Size Range (inches) | Common Applications |

| Heavy-Duty | 12 to 36 | Moves lots of material fast in tough jobs. |

| Ditching | 24 to 72 | Used for grading, cleaning ditches, roadwork, and site prep. |

| Tilting | 48 to 72 | Good for grading, landscaping, building golf courses, and trails. |

| Cemetery | 12 to 42 | Digs graves, pools, and does careful digging work. |

| Skeleton | 24 to 48 | Sorts and sifts materials, cleans sites, and helps with landscaping. |

| Pavement Removal | 18 to 36 | Used for demolition, fixing roads, and installing utilities. |

Always check the mini excavator bucket size chart before you buy or rent. This helps you avoid problems and keeps your machine safe.

Best Bucket Types for Mini Excavators

There are many bucket types for mini excavators. Some buckets are best for digging trenches. Others help with grading or tearing down things. The right bucket makes your job easier and faster.

| Bucket Width (inches) | Application | Impact on Performance |

| 12-24 | Trenching | Good for digging narrow and exact holes. |

| 30-36 | General excavation | Works well for many soil types and jobs. |

| 48-60 | Bulk earthmoving | Moves lots of dirt quickly and easily. |

The right bucket width gives you good power and depth.

A bucket that is too big can hurt the engine.

A bucket that is too small makes the job take longer.

Different brands have buckets made for certain soils.

When you choose a mini excavator bucket, match the width to your machine and job. Here are some steps to help you:

Check your mini excavator’s weight and size for the job.

Think about how much engine power you need for heavy work.

Look at how deep and far your excavator can dig.

Pick a bucket that fits your mini excavator and the job you have. This helps you get the best results and keeps your machine working well. Using the wrong bucket can slow you down or break your excavator. Always use the size chart and think about what you need to move. This will help you choose the best bucket for your project.

Tip: The right mini excavator bucket helps you dig faster and keeps your machine safe.

Practical Checklist for Bucket Selection

When you pick an excavator bucket, you need a plan. Look at your job site and what you will move. Check your machine’s details too. Use this checklist to help you choose well. This keeps your work safe and helps you finish faster.

Assessing Job Site & Material

First, look at the ground and what you need to dig. Different soils need different buckets. Here are some things to remember:

Sandy soils work best with general-purpose buckets. These buckets are wide and have strong sides for easy digging.

Silt soils need tilt buckets. Tilt buckets handle fine dirt and stop it from packing down.

Gravel soils need rock buckets. These buckets have strong teeth and tough frames for hard jobs.

Loam soils are good for general-purpose buckets. These buckets have medium teeth and balanced shapes for mixed dirt.

Always check the weight and type of material before picking a bucket.

Tip: Pick a bucket that matches the soil and job site. This helps you dig better and makes your bucket last longer.

Matching Bucket to Application

You need to pick a bucket that fits your job. Each bucket works best for certain tasks. Follow these steps:

Learn about each bucket type and what it does. For example, use a digging bucket for hard dirt or a rock bucket for heavy loads.

Pick the biggest bucket that fits your job. Think about how heavy the material is and the size of your truck.

Use smaller buckets for heavy stuff. This keeps your excavator safe and working well.

Make sure the bucket matches your job, like trenching, grading, or breaking things down.

| Application | Recommended Bucket Type | Notes on Capacity and Use |

| Digging in hard soil | Digging bucket | Choose strong teeth and right size |

| Moving sand | General-purpose bucket | Larger capacity helps efficiency |

| Handling gravel | Rock bucket | Reinforced for heavy material |

| Grading slopes | Tilt bucket | Smooth bottom for fine work |

Evaluating Machine Specs

Check your excavator’s details to make sure the bucket fits. Use this guide to help:

Look at your machine’s brand and model. Each brand has its own details.

Check the size and weight your excavator can handle. Bigger machines need stronger buckets.

Think about what you will use the bucket for and what you will move.

Read the maker’s weight tips to stop your machine from tipping over.

Check the bucket’s weight and compare it to your excavator’s weight.

Look at the rated load and the biggest bucket size your machine can use.

Use this quick guide to check if the bucket fits:

Measure the pin diameter.

Check the space between the pins.

Measure the gap between the mounting plates.

Note: Always use a spec guide to match the bucket size to your machine. This keeps your excavator safe and helps you get more done.

Excavator Bucket Compatibility

Fit & Coupler Types

You must check if the bucket fits your excavator. First, find your machine’s model and serial number. Look in the attachments catalog for your excavator. Use charts to see if the attachment will fit. Next, see if your machine uses a pin-on or quick attach coupler. Measure the mounting plate and the pin size. Make sure the bucket size matches your excavator’s lifting power. Spread the weight so the hydraulic system stays safe. Always follow the maker’s rules. If you are not sure, ask an expert for help. Check everything again before you put on a new bucket.

There are different coupler types for excavators:

Greased pins are good for direct mounting and last longer with oil.

Non-greased pins, or dummy pins, work with quick hitches and protect the coupler.

Dog bone pins let you use attachments on different excavator sizes by changing the pin size.

Hydraulic & Mechanical Considerations

When you pick a bucket, think about hydraulic and mechanical things. The table below shows what you should check:

| Consideration | Details |

| Material Choices | Steel is strong but heavy. Aluminum is lighter. Composite materials resist wear. |

| Build Quality | Look for strong welds, tough construction, and high-quality teeth. |

| Bucket Capacity | Width, length, and volume decide how much material you can move each time. |

Check your excavator’s hydraulic system to see if it can handle the bucket’s weight and size. A good match keeps your machine safe and helps it work well.

Attachments & Maintenance Tips

To keep your excavator bucket in good shape, follow these tips:

Check the bucket often for damage or wear.

Clean the bucket after you use it to get rid of dirt.

Put oil on moving parts to stop them from rubbing too much.

Keep the edges sharp so digging is easier and faster.

Fix or change worn parts right away.

Doing these things helps you avoid big repairs. Daily checks find small problems before they get worse. Many people say the YF Bucket works well for hard jobs and lasts longer if you take care of it. Cleaning and oiling the bucket often helps you use it for a long time.

Tip: Taking care of your excavator bucket helps it last longer and work better on every job.

To pick the right excavator bucket, do these things: First, make sure the size and how much it holds match your job and what you need to move. Next, choose the right bucket type for what you want to do. Then, check the bucket’s width, shape, and how it attaches to your excavator. Using a size chart and checklist helps you not make mistakes and keeps your work safe. Strong buckets, like the YF Bucket Excavator Bucket, last a long time and work well for hard jobs. If you are not sure, look at the maker’s guide or ask an expert to help you find the best bucket for your excavator and what you need to carry.

FAQ

How do you measure an excavator bucket?

You measure the width from edge to edge. You check the depth from the front lip to the back. You look at the height from the base to the top. Use a tape measure for accuracy.

What bucket size fits a 20-ton excavator?

Most 20-ton excavators use buckets between 36 and 60 inches wide. You should check your machine’s manual for exact recommendations. The YF Bucket Excavator Bucket fits this size range.

Can you use any bucket on your excavator?

No, you need a bucket that matches your excavator’s coupler type, pin size, and hydraulic system. Always check compatibility before you attach a new bucket.

How often should you inspect your excavator bucket?

You should inspect your bucket before each use. Look for cracks, worn teeth, and loose pins. Regular checks help you avoid breakdowns and keep your bucket working longer.

What is the difference between a general-purpose and a heavy-duty bucket?

A general-purpose bucket works best for soil, sand, and light materials. A heavy-duty bucket handles rocks, concrete, and tough jobs. Heavy-duty buckets use stronger steel and reinforced edges.