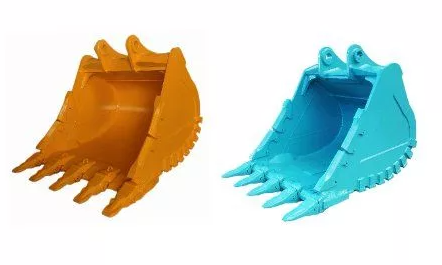

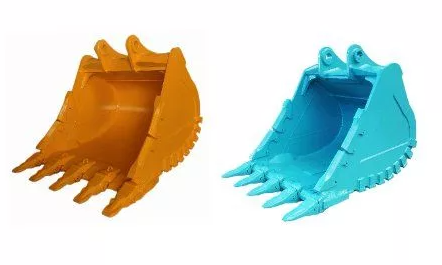

Excavator buckets are the primary tools for digging, loading, and moving materials across construction and mining sites. They endure heavy stress, abrasive materials, and daily exposure to dirt, moisture, and chemicals. Neglecting proper care can lead to premature wear, unexpected breakdowns, and costly repairs. Implementing a structured maintenance routine not only extends the bucket's lifespan but also improves operational efficiency, reduces fuel consumption, and minimizes downtime. In this guide, we provide comprehensive tips on cleaning, inspection, lubrication, repair, storage, and operator training to ensure your buckets remain in peak condition.

Regular Cleaning

Buckets accumulate dirt, mud, rocks, and other debris during every operation. Over time, this build-up accelerates abrasion, causes rust, and affects hydraulic performance.

Post-Use Cleaning: After completing each shift or major task, remove soil, stones, and debris using shovels or brushes.

High-Pressure Washing: For stubborn residues, especially clay or hardened mud, use a high-pressure water system to thoroughly clean the bucket's teeth, corners, and interior surfaces.

Drying: Ensure the bucket is completely dry before storage. Moist surfaces promote corrosion and shorten the metal's life.

Benefits: Maintaining a clean bucket prevents rust formation, reduces hydraulic drag, and ensures smoother, more efficient digging.

Regular cleaning is the first and most critical step in prolonging the life of your equipment, and it also helps operators identify early signs of wear or damage during routine maintenance.

Inspect for Wear and Damage

Frequent inspection allows you to catch minor issues before they evolve into major failures. Excavator buckets face extreme mechanical stress, and even small cracks or blunt teeth can reduce efficiency and safety.

Teeth: Look for cracks, chipping, or blunting. Worn teeth decrease penetration ability, increase fuel consumption, and strain the excavator arm.

Side Cutters and Adapters: Check for abrasion and uneven wear patterns. Side cutters protect the bucket shell from side impacts, so early replacement is critical.

Bucket Shell and Weld Joints: Inspect monthly for cracks, deformation, or signs of fatigue. Structural damage can compromise the integrity of the entire bucket.

| Component | Common Issue | Inspection Frequency |

| Teeth | Wear, breakage | Daily/Weekly |

| Side Cutters | Abrasion | Weekly |

| Bucket Shell | Cracks, deformation | Monthly |

Lubrication of Moving Parts

Buckets connect to excavator arms through pins, bushings, and pivot points. Friction at these points can cause rapid wear if not properly lubricated.

Grease Application: Apply manufacturer-recommended grease to all pivot points, pins and bushings regularly.

Avoid Over-Greasing: Excess lubricant attracts dust and dirt, which accelerates wear. Apply a thin, even layer.

Consistency: Establish a weekly or daily lubrication schedule depending on operational intensity.

Replace Worn Teeth and Adapters

Bucket teeth experience the most wear because they directly contact hard surfaces, rocks, and other abrasive materials. Maintaining sharp teeth is essential for operational efficiency.

Monitor Wear Patterns: Track the rate of wear on individual teeth. Replace teeth showing significant wear rather than the entire set when possible.

Use Quality Parts: High-quality OEM or aftermarket teeth ensure durability and consistent performance.

Operational Efficiency: Sharp teeth reduce digging resistance, improve penetration, and lower fuel consumption.

Protect Against Rust and Corrosion

Buckets are frequently exposed to wet, muddy, and chemically harsh environments. Rust and corrosion significantly shorten bucket life.

Rust-Preventive Coatings: Apply anti-corrosion coatings, paints, or oils to all metal surfaces.

Proper Storage: Store buckets in covered areas, away from standing water or chemical exposure.

Routine Checks: Inspect coating integrity regularly and reapply as needed.

Monitor Bucket Alignment

Misaligned buckets can cause uneven wear on teeth and side cutters, as well as additional strain on the excavator arm and hydraulic system.

Pin and Bushing Clearances: Check clearances regularly to ensure smooth movement.

Realignment: Adjust if the bucket leans, drags, or shows uneven contact with the material being dug.

Attachment Torque: Verify that all bolts and pins are correctly torqued to avoid misalignment during operation.

Welding and Repair

Minor cracks can expand rapidly under stress, leading to catastrophic bucket failure. Address welding needs promptly.

Timely Welding: Repair small cracks immediately before they grow.

Certified Welders: Always use trained professionals for structural repairs to ensure strength and durability.

Avoid Patch Repairs on High-Stress Areas: For heavily loaded sections, full replacement may be safer than temporary fixes.

Timely welding prevents costly structural failures, extends bucket life, and ensures consistent performance.

Storage and Handling

Correct storage and handling practices minimize accidental damage, deformation, and rust formation.

Proper Placement: Store buckets on solid, level ground with teeth facing upward to prevent bending.

Avoid Stacking: Never place heavy machinery on top of stored buckets.

Organize Pins and Parts: Keep removable parts neatly organized to prevent loss or corrosion.

Thoughtful storage protects the bucket's structural integrity, reduces wear, and simplifies maintenance tasks.

Track Usage and Hours

Keeping a detailed log of operating hours and wear patterns allows for proactive maintenance planning.

Daily Logging: Record hours of operation and the type of materials handled.

Track Wear: Note the condition of teeth, adapters, and the bucket shell.

Preventive Scheduling: Use usage data to plan maintenance rather than relying solely on calendar time.

Tracking usage optimizes maintenance cycles, reduces downtime, and allows accurate budgeting for repairs or replacements.

Training Operators

Operator habits have a direct impact on bucket longevity. Even a high-quality bucket can suffer premature wear if misused.

Efficient Digging Techniques: Train operators to avoid excessive side loading, minimize impact against rocks or concrete, and maintain smooth, consistent digging motion.

Awareness of Load: Encourage operators to adjust digging strategy based on soil type and material hardness.

Ongoing Education: Conduct regular refresher training sessions to reinforce best practices.

Skilled operators not only extend bucket life but also reduce fuel consumption, prevent damage, and enhance overall site productivity.

Conclusion

Proper maintenance of excavator buckets safeguards your investment and ensures operational efficiency. By implementing daily cleaning, frequent inspections, consistent lubrication, timely replacement of teeth, corrosion protection, alignment checks, welding, correct storage, usage tracking, and operator training, you can maximize productivity and reduce long-term costs.

Companies like YF Bucket provide durable, high-quality buckets engineered to withstand harsh working conditions, making maintenance simpler and more effective. Following these comprehensive practices ensures your buckets perform reliably, enhancing both safety and efficiency across every job site.

FAQ

Q: What is an Excavator Bucket?

A: An Excavator Bucket is a heavy-duty attachment used for digging, loading, and moving materials in construction and mining.

Q: How do I maintain my Excavator Bucket?

A: Follow excavator bucket maintenance tips like daily cleaning, inspection, and proper storage to reduce wear and extend life.

Q: Why is Excavator Bucket maintenance important?

A: Proper maintenance prevents downtime, reduces repair costs, and ensures optimal performance on every job site.